Why DIY Electrical Work Is Riskier in Winter

The deep chill of an Idaho Falls winter often drives homeowners indoors, providing the perfect opportunity to tackle those lingering home improvement projects. The temptation to quickly fix a flickering light, install a smart thermostat, or add a new outlet in the basement is strong, promising instant results and saving a little money. However, when it comes to electrical work, the risks involved are always significant, and during the winter months, those hazards are uniquely amplified.

Electrical work is fundamentally a safety trade that deals with invisible energy. When you combine this inherent risk with the heavy electrical loads, material stresses, and challenging access conditions of a harsh winter, the likelihood of a dangerous accident or a catastrophic system failure increases dramatically. DIY electrical work in cold weather creates a perfect storm of hazardous conditions that demand professional caution.

Ignoring the increased risk is never worth the minor savings. A seemingly simple DIY fix can lead to compromised safety, code violations, and, most critically, a serious electrical fire. For the safety of your home and family, understanding why winter electrical projects must be left to a licensed professional is essential.

The Increased Electrical Load and Fire Risk

Winter is the peak season for sustained electrical demand in Idaho Falls. Every system in the home is working harder and longer. Furnaces run constantly, electric water heaters cycle more frequently, and every home relies on supplemental heating devices, from space heaters to heating blankets. Holiday lighting and extended indoor entertaining further compound this consumption.

This high, sustained load pushes the electrical system to its absolute limits. Wires and panels that were already marginal during the mild summer months are now constantly stressed. A minor fault that was previously harmless becomes an immediate fire hazard under this maximum winter load. A common issue is the electrical service panel itself being undersized for the total winter demand, which can lead to rapid failure.

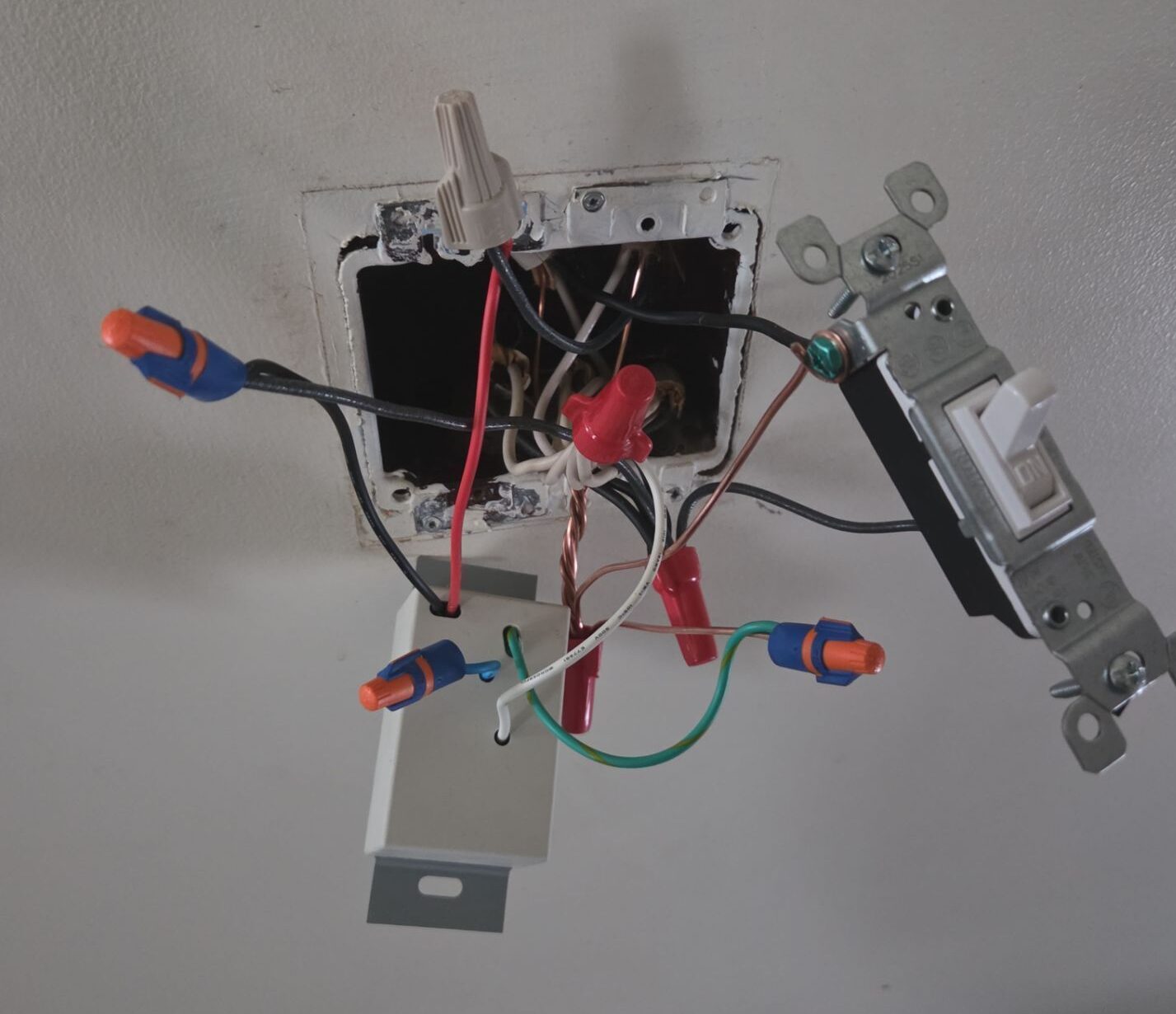

If a homeowner attempts to add a new circuit or plug a heavy-draw appliance into an existing line that is already maxed out, they create an immediate overload. The breaker should trip, but if the breaker is old or faulty, the wire insulation will overheat instead. Furthermore, amateur wiring connections, which are already prone to failure, are immediately tested by this high current. If a DIY connection is loose, arcing occurs, generating intense heat that can quickly ignite materials inside the wall cavity, especially when the home is sealed up tight against the cold.

Cold-Related Material Failure and Installation Errors

The winter environment itself creates physical conditions that make electrical components more likely to fail and installation mistakes more likely to occur. Electrical insulation and the protective sheathing on wiring are designed to withstand normal temperature fluctuations, but in extreme cold, they become stiff and brittle.

Working with cold, stiff wiring is challenging even for experienced professionals. For a DIY homeowner, attempting to bend or manipulate cold wires in cramped attic spaces, basements, or garages significantly increases the chance that the wire’s protective insulation will crack or break. This exposes the live copper wire, creating an immediate and severe shock hazard for anyone working near it. If the exposed wire contacts a metal object or another wire, it will cause a short circuit.

Need a panel upgrade? Click here for our electrical panel upgrade service.

The cold also compromises the quality of the workmanship. Working on small terminal screws and delicate wire connections with cold hands makes precise tightening difficult. Loose terminal screws are the number one cause of arcing and heat generation in an electrical system. The subsequent temperature cycling—heating up when the power is on and cooling when the furnace turns off—causes the materials to contract and expand, further loosening any connection that was not properly torqued, a necessary step that only professionals perform correctly.

Reduced Visibility and Access Challenges

Electrical work often requires access to the unconditioned parts of the home, such as attics and crawlspaces, which become extremely hazardous during an Idaho winter. These spaces are often dark, cluttered, and now subjected to sub zero temperatures or covered in ice.

A cold, uncomfortable environment rushes the homeowner to complete the task quickly, leading to shortcuts and mistakes. The homeowner may skip critical safety steps, such as properly securing a junction box cover or fully tightening a terminal screw. In frigid attics, reduced visibility combined with slippery surfaces increases the risk of tripping over loose wiring or, critically, accidentally stepping between joists and falling through the ceiling below.

Working outdoors on main service disconnects, heat pump wiring, or generator installations during snow or freezing rain is inherently dangerous. Moisture and ice introduce an immediate, severe electrocution risk. A licensed electrician is trained in safe lockout/tagout procedures and uses insulated tools and protective gear, understanding that even minor moisture can be fatal. For the amateur, the cold and the weather are significant liabilities that often override safety protocols.

The Impact on Home Safety Devices

The winter environment also compromises essential safety devices, and DIY work can make this worse. Ground Fault Circuit Interrupters (GFCIs) are vital for shock protection in damp areas like basements and garages. The cold and moisture can cause improperly installed GFCIs to fail, leaving the circuit unprotected. If a DIY homeowner ignores GFCI requirements when installing a new basement outlet, they are introducing a severe shock hazard right next to the water lines.

Want to know why you should hire a licensed electrician? Click here for more information.

Furthermore, any electrical work involving the HVAC system introduces potential cross hazards. DIY wiring near the furnace or air handler risks damaging the control board or the system’s primary wiring. If this damage occurs, the furnace could shut down on the coldest night of the year, leading to frozen pipes and catastrophic home damage.

There is also the safety concern related to Carbon Monoxide (CO). While CO is an HVAC issue, using supplemental heating methods (like unvented propane or kerosene heaters) in a basement to stay warm while performing DIY electrical work introduces an immediate, deadly CO hazard into the home. Electrical safety is intertwined with HVAC safety, and only a licensed professional can look at the system holistically.

The Financial and Legal Repercussions

The primary goal of DIY work is to save money, but with electrical systems, this decision almost always leads to greater financial loss. If a fire occurs due to unpermitted, amateur electrical work, the homeowner’s insurance claim can and often will be denied. Insurance policies require that electrical work be completed by licensed professionals and be compliant with the National Electrical Code. The entire financial loss of the home falls to the homeowner.

If the DIY work is discovered during a future home sale, a professional home inspection will flag it immediately. The homeowner will be forced to hire a licensed electrician to rip out the bad, unpermitted wiring and install the new system correctly, often under the duress of a pending closing date. This costly, last minute repair always totals more than the cost of the initial professional installation.

A professional licensed electrician, like Minuteman Services, carries the necessary liability insurance and workers’ compensation, protecting the homeowner from any financial exposure should an accident or damage occur during the work. When a DIY homeowner works on their own system, they assume all liability for any accidents, injuries, or property damage. This financial risk is simply not worth the minor cost saved on labor.

The Licensed Professional Advantage

Choosing Minuteman Services for winter electrical work provides a crucial level of security and expertise. Our electricians are licensed, trained, and accustomed to working safely in the demanding Idaho environment. We use specialized, insulated tools and equipment to perform work with the necessary precision and safety checks. We know the local codes and the specific wiring practices required to handle high winter loads.

Our team has the 45 years of combined experience needed to diagnose and fix problems correctly, ensuring that all connections are properly torqued, all components are correctly sized for the load, and all safety devices (GFCI/AFCI) are installed where required. We know that winter is when your electrical system is under maximum strain, and we ensure that every repair and installation is built to withstand that stress.

The appeal of saving money by tackling DIY electrical work in the winter is understandable, but the inherent dangers are severe. Cold temperatures increase the risk of material failure, high electrical loads increase the risk of fire, and the challenges of the season increase the risk of installation error. Electrical safety is non negotiable. Do not compromise the safety of your home, your family, or your financial security by attempting amateur repairs. Trust the licensed, experienced professionals at Minuteman Services to handle your winter electrical needs safely and correctly.